We set the bar high for energy-using products that last

Our homes and workplaces are full of energy-using products – from phones and tablets, computers and printers, servers, to washing machines. In 2025, ECOS work on material efficiency helped to prolong the life of these products, saving energy for the planet and money for consumers. Here’s how.

Reduce, reuse, repair, recycle! We see these circular words often. How can they be put into action?

It all starts with design.

If products are designed from the outset to be more sustainable and durable, they will last longer. Instead of being replaced by new products, they will be repaired. Instead of being incinerated or dumped, they will be recycled. We must move away from the linear economy of make, use, and dispose – which overshoots our planet’s boundaries – aiming for material efficiency instead.

Every product or spare part has an expiry date, but there are ways to postpone it as much as possible. ECOS helps to make that happen through standards and policy, advocating for the best methods of extending a product’s life to become widespread.

Designing products that are sustainable

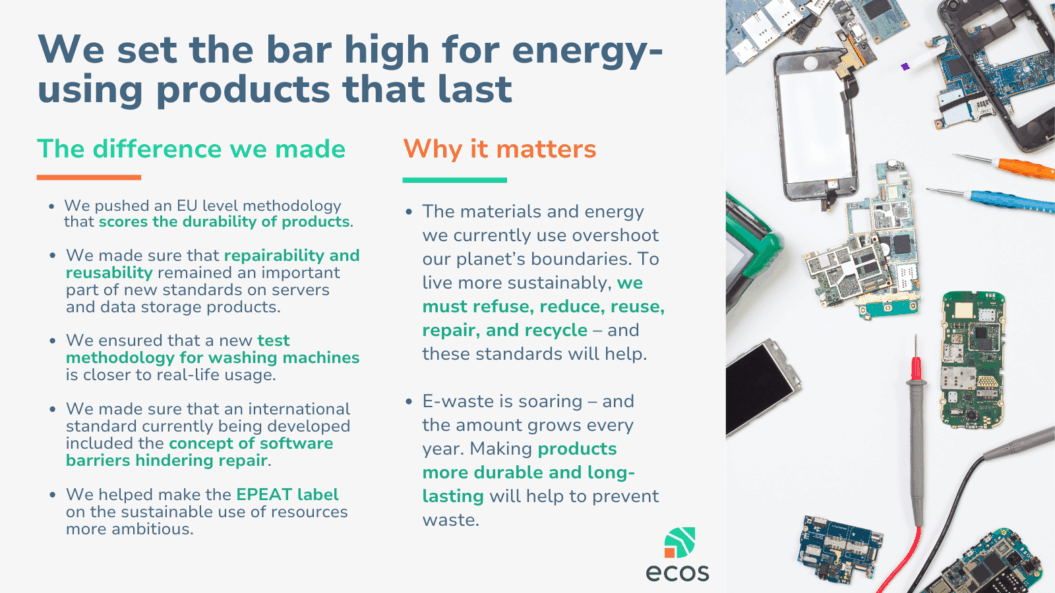

ECOS works to make legal requirements and voluntary commitments on the reliability, repairability, reusability, and remanufacturability of products as ambitious as they can be.

In 2025, we participated in no less than five complex standardisation and labelling processes related to the material efficiency of products, including on servers and data storage products, washing machines, electronics, and energy-related products in general.

We made sure that a durability scoring method was included in the European standard EN 45552:2020 on the durability of energy-related products. We also heavily contributed to the revision of another European standard, which ECOS helped develop back in 2020, EN 45554:2020 on the repair, reuse and upgrade of energy-related products. This standard is now being used as a source of inspiration for an international standard, too. Thanks to ECOS, the current draft of the international standard contains a new scoring parameter about serialisation (also called part pairing), an issue that currently prevents independent repairers from easily replacing spare parts.

We played a key role in ensuring that electronics and ICT products become more circular. For example, we worked to align the Global Electronics Council’s revised EPEAT criteria (an international label on the sustainability of ICT and electronic products such as laptops, smartphones, printers and electronic displays) with the EU’s ecodesign requirements for smartphones and tablets, as well as draft regulations for computers and printers. Similarly, on servers and data storage, we contributed to new European standards and their international equivalent, which will help market surveillance authorities verify compliance of these products with the EU’s ecodesign requirements on disassemblability, updates and data deletion.

Under the auspices of the reaLIFEstandards project, and in collaboration with the consumer organisation ANEC, we also made sure that a new European standard lays the basis for more durable washing machines – one of the most widely used appliances in European homes. This is the first standard of its kind, and we hope it will be used as a blueprint for other household appliances and consumer electronics in the future.

Ambitious standards are the answer

Without these standards, there would be no harmonised way to determine the resource efficiency of products, or to verify the reliability or circularity claims. We will continue working to raise the ambition of all these standards in 2026, to make sure all products are made to last – in every way possible.